Q.5 The fusion energy programme in India has steadily evolved over the past few decades. Mention India’s contributions to the international fusion energy project—International Thermonuclear Experimental Reactor (ITER). What will be the implications of the success of this project for the future of global energy? (10 marks, 150 words)

What is fusion?

Fusion is the Sun’s engine: very light nuclei (typically deuterium–tritium) fuse at extreme temperatures, releasing huge energy. On Earth this needs a magnetic “bottle” called a tokamak to confine the ultra-hot plasma. Fuel is widely available (deuterium in seawater; tritium can be bred from lithium) and long-lived waste is far lower than in fission.

What is ITER?

The International Thermonuclear Experimental Reactor (ITER) in France is a global tokamak designed to demonstrate a self-heating, or “burning,” plasma—a science proof-of-concept for future power plants. ITER will not produce electricity; it is the bridge to DEMO-class reactors.

India’s journey and concrete contributions

- Domestic base: From ADITYA and SST-1 tokamaks at the Institute for Plasma Research (IPR) to a dedicated ITER-India (DAE) team, India has steadily built plasma, materials and cryogenics expertise.

- Cryostat leadership: India designed, fabricated and assembled the world’s largest stainless-steel cryostat—the vacuum shell that houses ITER’s core.

- Cryogenics and cooling: Supply of cryolines and major cooling-water/heat-rejection systems that keep the machine stable.

- Shielding and diagnostics: In-vessel/in-wall shielding and selected diagnostic systems for protection and precise measurements.

- Power and controls: Elements of high-power heating/power supplies and control & instrumentation.

- Test Blanket Module (R&D): Work towards lithium-based breeder modules, vital for tritium self-sufficiency in future plants.

- Capability gains: Precision fabrication, ultra-high vacuum, cryogenics, quality systems, and project management—Make-in-India for high-tech.

Why ITER’s success matters—especially for India

- Firm, low-carbon baseload complementing solar/wind; cleaner air and lower import bills.

- Shorter-lived waste and strong inherent safety, aiding public acceptance.

- Industrial lift-off: New supply chains in magnets, cryogenics, advanced materials; high-skill jobs for Indian youth.

- Synergies: Green hydrogen production and desalination for water-stressed coasts; greater energy security.

Reality check: Fusion is decades-scale. India should back ITER while expanding renewables, storage, efficiency and safe fission. If ITER works, India is well-placed—scientifically and industrially—to be a front-rank fusion nation.

Q.6 How can India achieve energy independence by 2047 through clean technologies? In what ways can biotechnology play a significant role in this effort? (10 marks, 150 words)

Introduction (human angle):

Energy independence is not only about macro numbers; it is about a household’s monthly bill, the air a child breathes on the way to school, and whether a small workshop can afford reliable power. By 2047, India can cut fossil imports and still keep energy reliable, affordable and clean by combining renewables, hydrogen, electrification, efficiency and biotechnology.

Clean-tech pillars (practical levers):

- Renewables + storage at scale: Solar and wind with batteries and pumped hydro; fewer blackouts, fewer diesel gensets in neighbourhoods.

- Smarter, flexible grids: Digital controls, demand response, time-of-day tariffs; consumers become partners, not just payers.

- Electrify & save: Efficient motors, heat pumps in industry; better appliances and retrofits in buildings; public transport and EVs to cut tailpipe pollution.

- Green hydrogen: Decarbonise refineries, fertilisers, steel and heavy transport; build domestic electrolyser and RE manufacturing to create jobs at home.

- Critical-mineral security & circularity: Recycling batteries/solar gear; local supply chains to protect small businesses from global shocks.

Where biotechnology makes a people-level difference:

- Advanced biofuels: 2G ethanol, compressed biogas, and sustainable aviation fuel from agri/municipal waste—cleaner cities, extra income for farmers, less stubble burning.

- Biocatalysis & synthetic biology: Enzyme/microbial routes to green chemicals and bioplastics; potential bio-hydrogen; safer workplaces.

- BECCS & algal systems: Negative-emissions options that pair climate responsibility with new rural industries.

- Agro-biotech: Water-smart crops, biofertilisers/biostimulants—lower input bills, healthier soils, reduced import dependence.

Enablers (fair transition):

Stable policies, concessional green finance, carbon markets, quality standards, strong R&D-skills missions, and worker reskilling so the transition is just.

Conclusion:

A humane path to 2047 blends renewables + hydrogen + efficiency + biotech with circular manufacturing and smarter grids—cleaner air, lower import bills, and local jobs that let families plan their futures with confidence.

Q.7 What is Carbon Capture, Utilization and Storage (CCUS)? What is the potential role of CCUS in tackling climate change? (10 marks, 150 words)

Introduction (idea in plain words):

CCUS prevents carbon dioxide from reaching the atmosphere by capturing it at source (cement, steel, refineries, power) or from air, transporting it, then either using it in products or storing it safely underground. It is not a substitute for renewables and efficiency, but a targeted tool for the toughest emissions.

What CCUS involves:

- Capture: Post-combustion, pre-combustion, or oxy-fuel routes; growing interest in direct air capture.

- Transport: CO₂ pipelines/ships with safety standards.

- Utilization: Conversion to e-fuels, carbonates, chemicals, building materials.

- Storage: Injection into saline aquifers or depleted oil–gas fields with robust MRV (monitoring, reporting, verification).

How CCUS helps tackle climate change:

- Hard-to-abate sectors: Addresses process CO₂ (e.g., clinker in cement) where alternatives are limited.

- Negative emissions: BECCS/DACCS can remove legacy carbon to balance residual emissions.

- Transition bridge: Buys time while grids, hydrogen, circular materials scale; keeps industries running as they decarbonise.

- Industrial opportunity: New value chains (capture equipment, CO₂-derived products), high-skill jobs.

Guardrails (to make it credible):

- Use low-carbon power for capture to avoid rebound; build CO₂ hubs and pipelines; clear liability rules; align with carbon pricing/standards so CCUS complements, not delays, renewables and efficiency.

Conclusion:

CCUS is the ‘surgical’ decarbonisation tool—essential for hard sectors and net-zero balancing, effective only with strong policy, transparent MRV, and clean energy inputs.

Q.15 How does nanotechnology offer significant advancements in agriculture? How can this technology help uplift the socio-economic status of farmers? (15 marks, 250 words)

Context (big idea):

Nanotechnology enables precision at tiny scales—delivering inputs smarter, sensing conditions earlier, and reducing waste. Used responsibly, it can raise yields, cut costs, and reduce chemical burdens—directly improving farmer livelihoods.

- Technological advances (how it helps on-farm):

- Nano-fertilisers/pesticides: Higher surface area and controlled release → lower doses, better uptake, fewer sprays, reduced run-off.

- Seed priming/coatings: Faster germination, stronger seedlings, stress tolerance (drought/heat/salinity).

- Nano-sensors: In-field, low-cost sensing of soil moisture/nutrients/disease → precision irrigation and dosing via IoT advisories.

- Water solutions: Nano-membranes/photocatalysts for on-farm water purification and reuse.

- Smart packaging: Nano-films/antimicrobial coatings extend shelf life, cutting post-harvest losses.

- Soil health interfaces: Nano-enabled amendments (e.g., with biochar) to enhance nutrient-use efficiency and microbiome activity.

- Socio-economic uplift (pathways to income gains):

- Higher net returns: Less input per acre + steadier yields → stronger cost–benefit for smallholders.

- Quality premiums: Better grades/longer shelf life open processing/export markets.

- Risk reduction: Early-warning sensors reduce crop failure; improves creditworthiness and insurance uptake.

- New rural jobs: Local manufacture/servicing of nano-inputs, sensor networks, testing/extension services.

- Environmental dividend: Lower chemical loads → cleaner water/soil, long-run productivity, community health.

- Guardrails (safe, affordable scale-up):

Robust biosafety/residue standards, farmer training, cooperative/FPO-based access to keep costs low, and public R&D–industry partnerships to localise production.

Bottom line:

With safety and affordability at the core, nanotech can shift Indian agriculture from heavy inputs to smart precision, raising farmer incomes while healing soils and water.

Share This Story, Choose Your Platform!

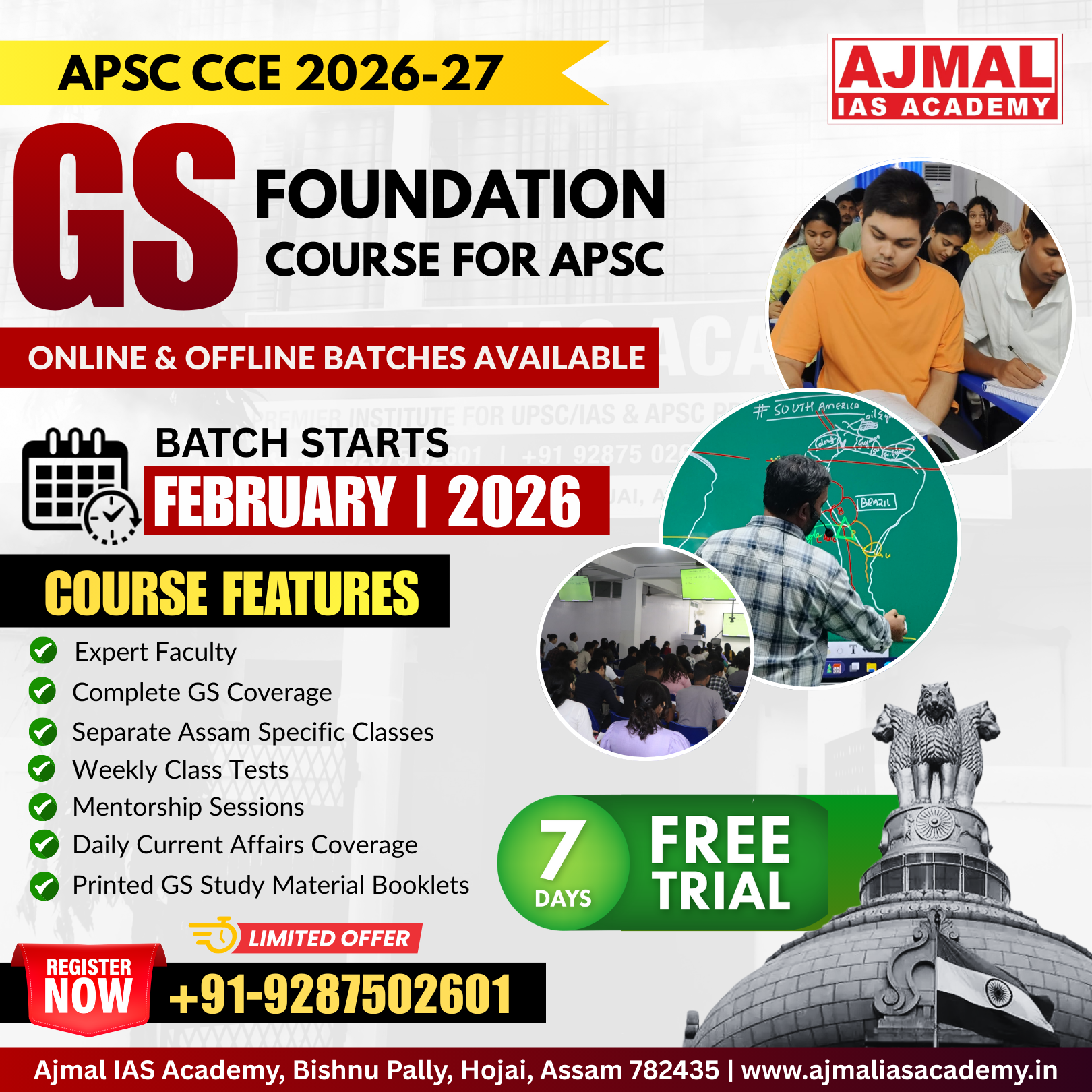

Start Yours at Ajmal IAS – with Mentorship StrategyDisciplineClarityResults that Drives Success

Your dream deserves this moment — begin it here.