Overview

Rare earths are key to everyday technology—phones, wind turbines, medical scanners, missiles, and electric cars. These 17 elements are abundant in the crust but hard to separate, refine, and turn into magnets. China dominates mid-stream steps (separation, metals, alloys, magnet making), giving it economic and geopolitical leverage as the world electrifies transport and power.

What exactly are rare earths and why they matter

- Family: 15 lanthanides plus Scandium and Yttrium.

- Magic property: Alloyed to make high-energy permanent magnets—compact and powerful.

- Strategic pull: Needed in clean-energy targets, defence electronics, and precision manufacturing.

Key elements and their usage

| Element (group) | Core role | Applications |

|---|---|---|

| Neodymium + Praseodymium (light) | High-power Nd-Fe-B magnets | Electric-car motors, wind turbines, robotics |

| Dysprosium / Terbium (heavy) | Heat-stable magnets | Traction motors, defence actuators |

| Lanthanum / Cerium (light) | Catalysts, glass polishing | Refineries, catalytic converters, optics |

| Yttrium / Europium / Terbium (heavy) | Phosphors, specialty ceramics | Displays, lasers, sensors |

| Samarium + Cobalt | Heat-stable magnets | Aerospace and defence electronics |

Bottleneck

The main challenge is not geology but processing. Solvent extraction involves hundreds of steps, creates radioactive waste, and requires scale and skill—China dominates here. Export licenses and standards can become geo-economic levers.

Global diversification

- New & revived projects: Mountain Pass (USA), Lynas (Australia), EU’s Critical Raw Materials push.

- Alliances & finance: Minerals Security Partnership, public-private funds for separation and magnet recycling.

- Circular economy: Recycling of wind rotors, hard-disk drives, motors as secondary sources of rare-earth magnets.

India’s position: promise and gaps

- Geology: Monazite-bearing beach sands (Kerala, Tamil Nadu, Odisha, Andhra Pradesh) and inland alkaline complexes.

- Capability: IREL recovers mixed compounds; separation, alloys, and magnets remain limited.

- Policy moves: National critical-minerals list, overseas sourcing via Khanij Bidesh India Limited, tech partnerships, growing EV & wind demand.

- Bottlenecks: Atomic mineral rules, few large separation parks, environmental clearance, limited domestic magnet industry.

India’s ore-to-magnet plan

| Step | Where India is | What to fix next |

|---|---|---|

| Exploration | Beach sands mapped; inland patchy | Airborne geophysics, targeted drilling of alkaline complexes |

| Separation / refining | Small solvent-extraction capacity | Coastal mid-stream parks with zero-liquid discharge & lined waste cells |

| Metals & alloys | Nascent | Technology tie-ups; viability support for first plants |

| Magnets | Very limited | Production-linked incentive for magnets tied to domestic motor orders |

| Recycling | Early pilots | Mandatory take-back; magnet-to-magnet programmes |

Practical roadmap

- Scale mid-stream safely: separation clusters with radiation & waste safeguards.

- Create domestic magnet base: incentivise powders, sintering, coatings; co-develop dysprosium-lean grades.

- Lock in overseas supply: equi

Share This Story, Choose Your Platform!

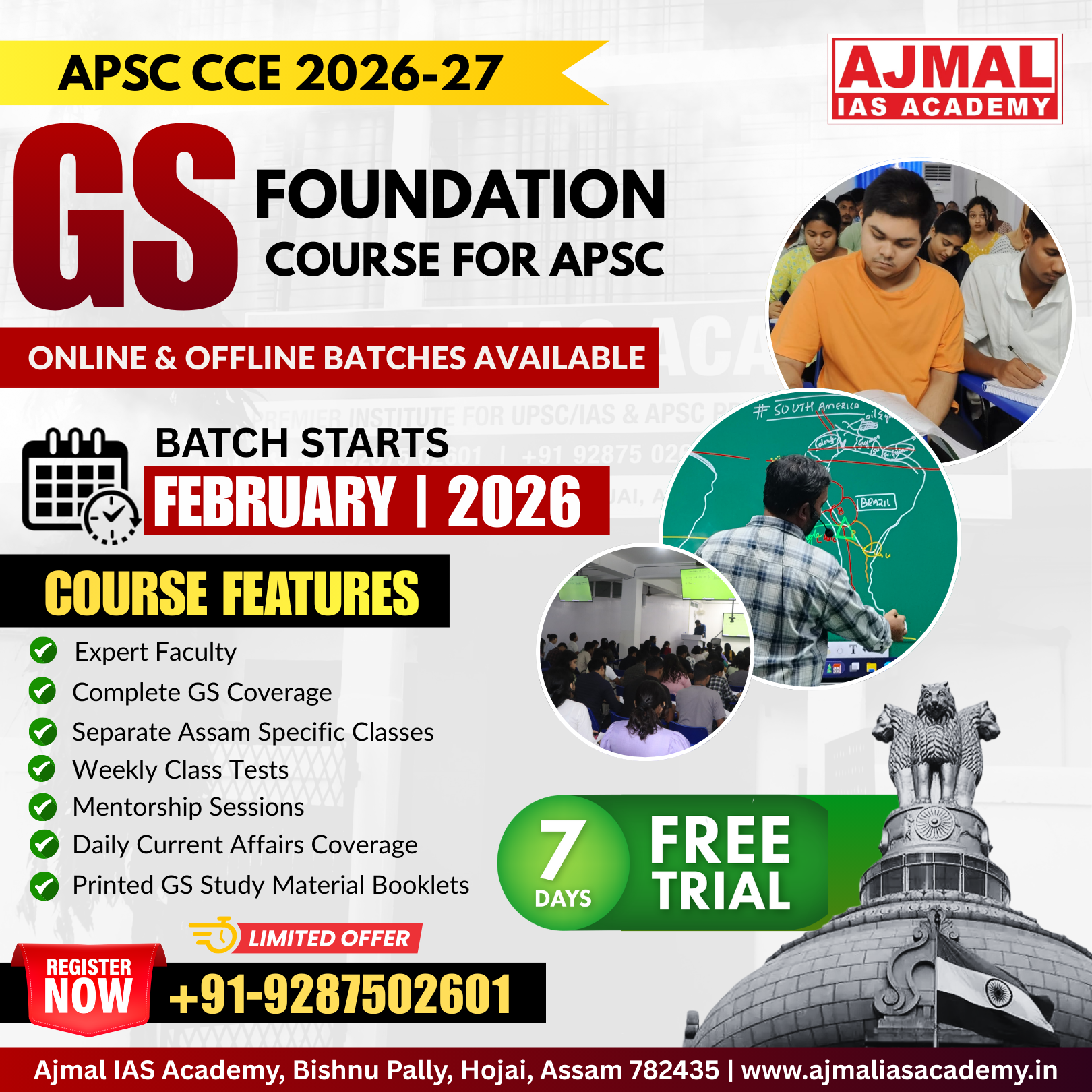

Start Yours at Ajmal IAS – with Mentorship StrategyDisciplineClarityResults that Drives Success

Your dream deserves this moment — begin it here.