Syllabus: GS–III & V: Infrastructure

Why in the news?

With the expansion of Numaligarh Refinery, operational stabilisation at BCPL Dibrugarh, and new capacities at Assam Petrochemicals Limited, Namrup, Assam is entering a phase where petrochemicals—not just petroleum fuels—can drive industrialisation, jobs, and MSME growth.

Oil & Petroleum Industry in Assam

Prelims One-linerDigboi in Assam is the birthplace of India’s oil industry and houses Asia’s first oil refinery.

Assam-Arakan Basin

|

Why petrochemicals matter

- Petrochemicals are growth multipliers: one petrochemical unit typically supports 10–12 downstream industries, creating jobs, entrepreneurship, and industrial clusters.

- Across India, the petrochemical value chain supports about 50 lakh jobs (direct and indirect).

- Unlike fuel refining, petrochemicals feed manufacturing, from plastics and textiles to pharmaceuticals, electronics, and automobiles.

Assam’s missed opportunity—and the turning point

- Assam has long produced oil and gas, but growth remained fuel-centric, with limited downstream manufacturing.

- A historical example is Bongaigaon Refinery, which once housed a petrochemical complex (xylene, DMT, polyester staple fibre).

- These units shut down by 2005 due to weak economics and intense competition, highlighting the risks of operating without a supportive ecosystem.

- The current phase is different: scale, integration, and policy alignment now favour petrochemical-led growth.

Key engines of the new petrochemical push

- Numaligarh Refinery Limited

- Expansion includes a polypropylene unit integrated with a petrochemical fluid catalytic cracking unit.

- This refinery–petrochemical integration will convert propylene-rich streams into polypropylene.

- Focus products include raffia-grade polymers (for woven sacks, ropes, industrial textiles) and non-woven grades (for hygiene and medical products), both high-demand segments.

- Brahmaputra Cracker and Polymer Limited

- Set up as a socio-economic commitment to the Northeast, it produces polymers but currently sells most output outside the region due to a weak local downstream base.

- New projects—butene recovery and hydrogenation pyrolysis gasoline stage-II—will improve efficiency, reduce logistics costs, and enable higher-value products.

- BCPL is also considering smaller downstream units within its premises, offering shorter gestation periods for investors.

- Assam Petrochemicals Limited

- With over five decades of operation, APL has commissioned a 500-tonne-per-day methanol plant, expanding beyond its older 100-tonne-per-day unit.

- Formalin capacity has increased, tapping a robust and diversified market.

- India currently imports about 94 percent of its methanol demand, making APL strategically important.

- Co-location with the upcoming ammonia–urea complex at Namrup offers strong technical and economic synergy.

Favourable national policy environment

- Rising domestic demand for tailor-made polymers and chemical intermediates across sectors such as automobiles, electronics, construction, pharmaceuticals, plastics, and textiles.

- Government initiatives include 100 percent foreign direct investment via automatic route, Petroleum, Chemicals and Petrochemicals Investment Regions, and plastic parks.

- Public sector companies are scaling up capacity to reduce import dependence, aligning with India’s manufacturing and self-reliance goals.

What Assam needs to do next

- Build a downstream ecosystem, especially for micro, small and medium enterprises, to convert feedstock availability into local manufacturing.

- Cluster-based development near refineries and petrochemical plants to reduce logistics costs and attract investors.

- Skill development and entrepreneurship support to ensure local employment gains.

- Environmental safeguards and modern technologies to ensure sustainable industrialisation.

Why this matters for Assam and the Northeast

- Petrochemicals can diversify Assam’s economy beyond extraction and fuels.

- They can generate large-scale employment, strengthen state revenues, and anchor manufacturing-led growth.

- With pipelines, feedstock availability, and integrated plants now in place, the region no longer needs to remain a peripheral supplier of raw hydrocarbons.

Exam Hook – Key Takeaways

- Petrochemicals act as industrial multipliers, enabling downstream manufacturing and jobs.

- Assam’s shift from fuel refining to refinery–petrochemical integration marks a structural economic transition.

Mains:

Discuss how petrochemical-led industrialisation can transform Assam’s economy and outline the policy measures needed to maximise downstream manufacturing and employment.

Share This Story, Choose Your Platform!

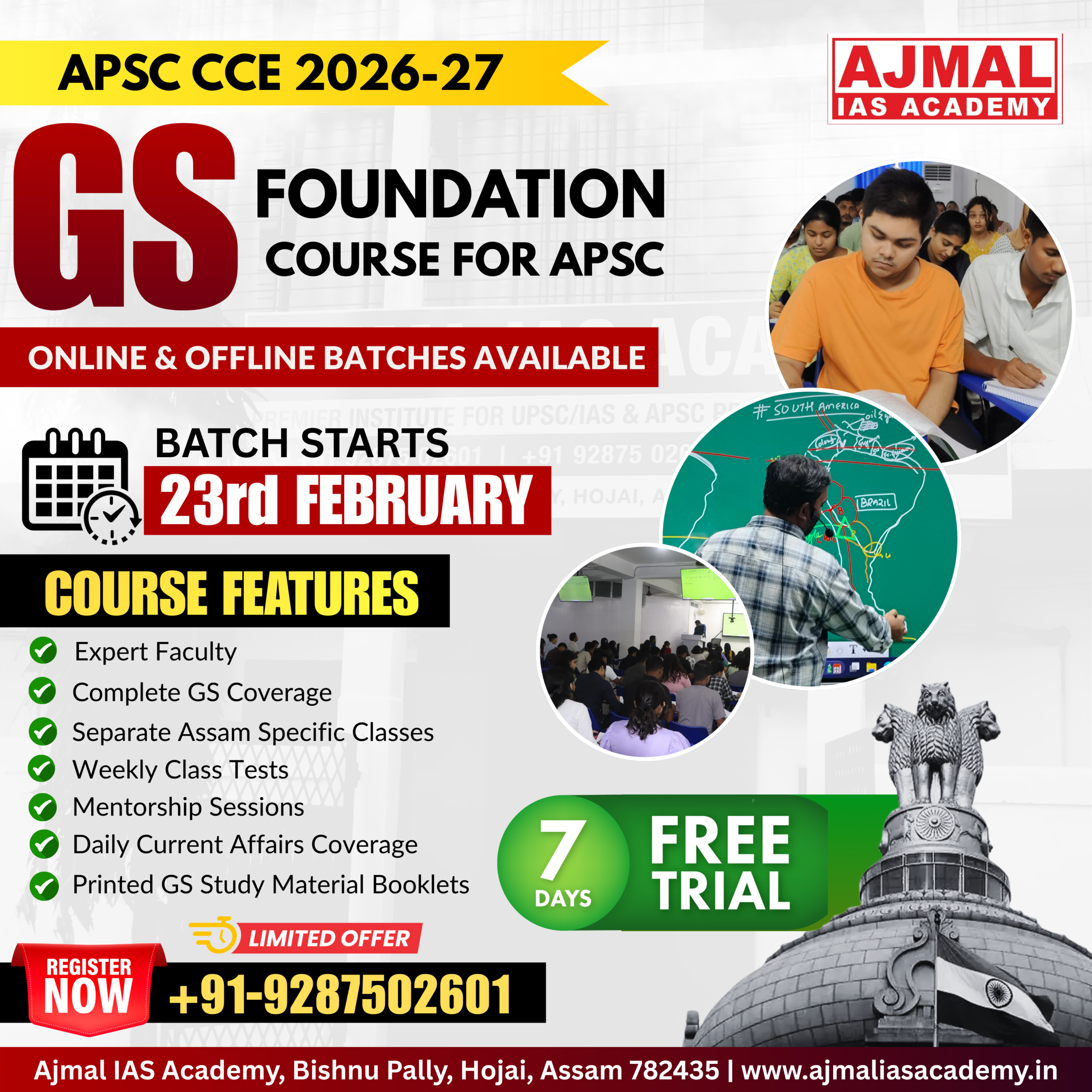

Start Yours at Ajmal IAS – with Mentorship StrategyDisciplineClarityResults that Drives Success

Your dream deserves this moment — begin it here.