Relevance: GS III (Economy – Infrastructure/Energy) & GS III (Science & Tech – Indigenization) | Source: Indian Express / MNRE Reports

1. The Context: A “Capex” Course Correction

The Ministry of Finance and MNRE are discussing a major shift in policy. They are considering a separate Capex (Capital Expenditure) Subsidy for the “upstream” segments of solar manufacturing (polysilicon, ingots, and wafers).

- The Problem: The existing PLI Scheme (Production Linked Incentive) works on an “output basis”—you get money after you sell the product.

- The Reality: This works for “downstream” units (assembling modules) which are cheaper to set up. But “upstream” plants (making polysilicon from raw silica) require massive upfront capital and cheap electricity, which the current PLI doesn’t cover effectively.

2. The “Missing Link” (Data for Mains)

India’s solar story is currently lopsided. While we are great at assembling the final product, we import almost all the ingredients.

- Downstream Success: Module manufacturing has achieved 59% of its PLI capacity targets. India now has a robust module capacity.

- Upstream Failure:

- Polysilicon: Only 14% of targeted capacity achieved.

- Wafers/Ingots: Only 10% achieved.

- Commercial Reality: As of 2025, India has negligible commercial production of polysilicon, leaving us ~80-90% dependent on China for the core raw material.

3. Why Upstream is Harder? (The Science)

Making a solar panel involves four steps. India is strong in Step 4 but absent in Steps 1-3:

- Polysilicon: Refining raw silica sand into 99.999% pure silicon. ( High Capital + High Electricity Intensity).

- Ingots: Melting silicon into large cylindrical blocks.

- Wafers: Slicing ingots into paper-thin sheets.

- Cells & Modules: Assembling wafers into blue/black squares (Cells) and framing them (Modules).

4. Strategic Importance

- Energy Security: Without domestic polysilicon, our “Green Energy” is essentially dependent on imports. A geopolitical standoff could choke our solar supply chain.

- Net Zero 2070: To hit the 500 GW renewable target by 2030, India needs resilient supply chains. We cannot build 30-40 GW of solar plants annually if we rely on imported wafers.

UPSC Value Box

| Concept / Term | Relevance for Prelims |

| Upstream vs Downstream | Upstream: Raw material processing (Polysilicon $\rightarrow$ Ingots $\rightarrow$ Wafers). Downstream: Assembly and finishing (Cells $\rightarrow$ Modules). |

| Vertical Integration | The strategy where a single company owns the entire supply chain (from Polysilicon to Modules) to reduce costs and dependency. |

| ALMM (Approved List of Models & Manufacturers) | A list by MNRE. Only manufacturers on this list can be used for government-backed solar projects. It acts as a Non-Tariff Barrier to check low-quality imports. |

Q. With reference to the solar photovoltaic (PV) manufacturing ecosystem in India, consider the following statements:

- “Upstream” manufacturing refers to the final assembly of solar cells into modules.

- The Approved List of Models and Manufacturers (ALMM) is maintained by the Ministry of Power to regulate thermal power equipment.

- Polysilicon production is a highly electricity-intensive process compared to module assembly.

Which of the statements given above is/are correct?

(a) 1 and 2 only

(b) 3 only

(c) 1 and 3 only

(d) 2 and 3 only

Share This Story, Choose Your Platform!

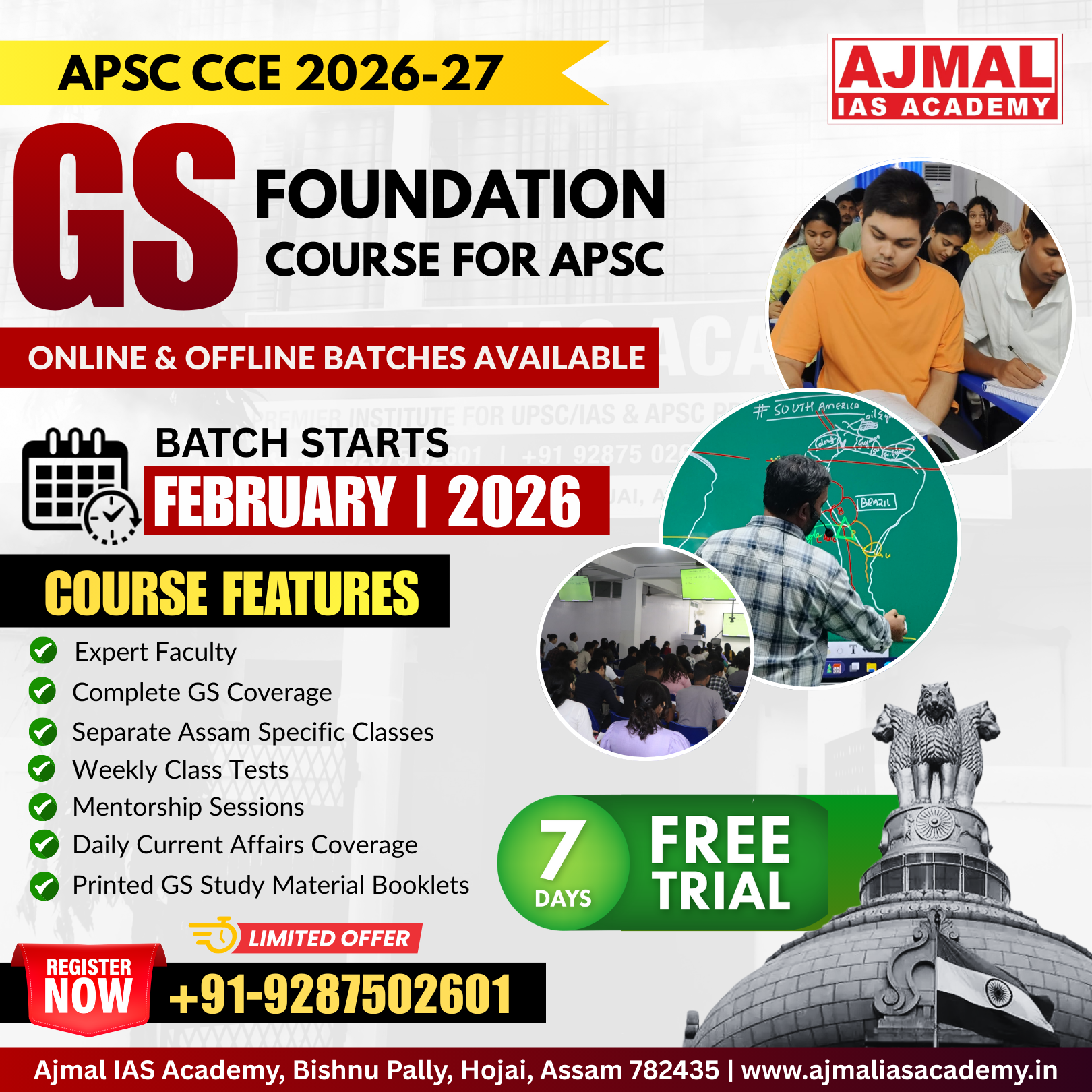

Start Yours at Ajmal IAS – with Mentorship StrategyDisciplineClarityResults that Drives Success

Your dream deserves this moment — begin it here.